Induction Sealing Wads

Induction sealing is a simple process by which an aluminium foil disc is sealed on the mouth of a container/bottle to ensure the safety of the product inside. This is done by placing the foil disc inside the cap and allowing the bottle to pass under the induction sealer after the filling and capping process. The induction seal is constructed to evenly seal the rim of the container once the container is capped and electronically heated.

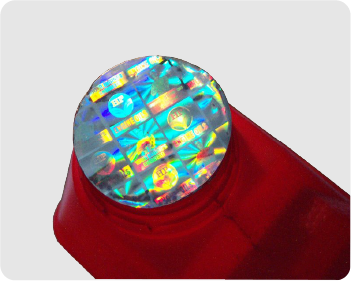

An induction sealing wads protects the contents from spillage and contamination. It also makes the container pilfer proof. With holography the induction wads are rendered even more secure. Once the cap is opened, the holographic induction seal will be visible as the assurance of genuineness and has to be punctured to access the contents. This ensures that the container cannot be recycled with a spurious product inside.

Holoflex produces induction sealing wads suitable for application on a wide range of HDPE, PE, PP, PET and glass containers. These wads are popularly used by Pharmaceutical, Lubricant, Insecticide and Pesticide, FMCG and Chemical Industries.

FAQs

Yes, induction sealing is a much better option as it is a reliable sealing technique, subject to the optimised machine setting and material selection. It can be tested for strength using a drop test to check its sustainability under harsh transportation condition.

The primary advantages are:

Leak Proof: As it provides uniform contact on the mouth of the container thereby providing 100% seal.

Tamper-Evident: The seal applied through induction sealing process cannot be removed without leaving –evidence of tampering. Security features like holography further prevents counterfeiting.

Higher Shelf-life: As Induction sealing is 100% air tight and spill proof and it retains the freshness of the contents for longer. It also prevents spillage and evaporation.

Induction sealing can be done on almost any kind of containers having a cap and uniform mouth surface to ensure a consistent seal. All kind of bottles and jars made with HDPE, LDPE, PET, PP and Glass may be sealed with such seals.

Induction sealing can be made more secure and more attractive using Holography which would impart holographic security features to the induction seal. Such brand protection invariably leads to greater band loyalty and recall.

Holographic wads can be used just like the normal wads and no modification is required

We can provide wads that can be used for food contact.

Yes. Our induction sealing wads can work on glass containers also.

No, we do not deal in induction sealing machinery. However, after assessing your requirement we can recommend a suitable induction sealing machine manufacturer.

We recommend storage in 25° Celsius temperature and 65% Relative Humidity in a dry area. If stored in its original packaging, the wads can be used up to 3 months from despatch.